The University of Windsor’s annual Engineering Research Open House was like a farmer’s market where each booth was bursting with fresh technology and innovation ripe for the plucking.

“It’s an open house for industry and government representatives,” said Kristie Pearce, communications coordinator for the faculty of engineering. “We invite them here to see how we work with industry and to see how we can help them out.”

Nearly 100 industry reps from across the region signed up to tour the various displays and labs at the Ed Lumley Centre for Engineering Innovation on Friday.

Faculty members and graduate students armed with laptops, samples and display boards were at the ready to explain everything from solar-powered greenhouses and electric vehicle research to 3D-printed mannequins for medical training.

Professor Jill Urbanic’s display around additive manufacturing (3D printing) research was two-fold. One section showed the medical training mannequins a collaborative team has been working on for more than two years. One 3D mannequin of the rib cage and chest, for example, has been designed to train students on performing a thoracentesis. The procedure involves inserting a needle with great precision into the chest to remove fluid or air.

“We have ideas on how to do things differently and we’re developing new technologies.”

The mannequin has been designed to mimic the resistance felt against skin and muscle as the needle moves through the body at the appropriate angle. Researchers studied cadavers to accurately recreate the 3D model.

Urbanic’s team is seeking industry partners to produce mannequins for other medical training procedures.

The other half of her display focused on 3D metals which could eventually be used in the production of service parts for the automotive industry.

“Metal additive manufacturing is the future,” Urbanic said. “We have ideas on how to do things differently and we’re developing new technologies.”

Professor Rupp Carriveau’s display outlined strategies for supplying the greenhouse industry with solar energy.

“More and more greenhouses are using lights and it’s putting a strain on the existing grid, both the gas grid and electricity. If we can put more generation on-site it helps the grid function better,” he said. “The capital cost of solar is still coming down. You can’t say the same about fossil fuels.”

Carriveau’s project of almost two years has involved developing “the most comprehensive model of greenhouse” in Staples, near Leamington, so the technology can be tested against real-time conditions.

He hopes another round of research funding will allow the team to embark on a pilot project.

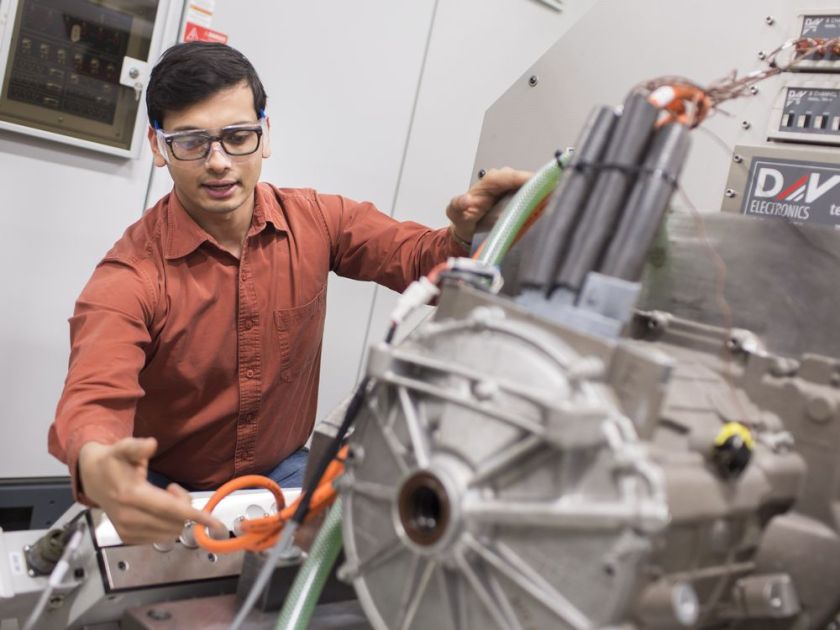

The Centre for Hybrid Automotive Research and Green Energy was opened for tours and, several years ago, guide Eshann Ghosh walked Sergio Marchionne, the late CEO of Fiat Chrysler, through the lab.

Ghosh, an engineering R&D manager, pointed out four electric-powered motors designed and tested by students.

He motioned to an electric power train tester that can “emulate what it would be like driving anywhere in the world. You can literally simulate driving in Alaska or Arizona.”

Other displays presented Friday focused on flexible manufacturing systems, wearable smart devices and lightweight vehicle materials.

Source: U of W Engineers Host ‘Open House for Industry’ Filled with New Ideas

Written By: Mary Caton